Absorption microscopes

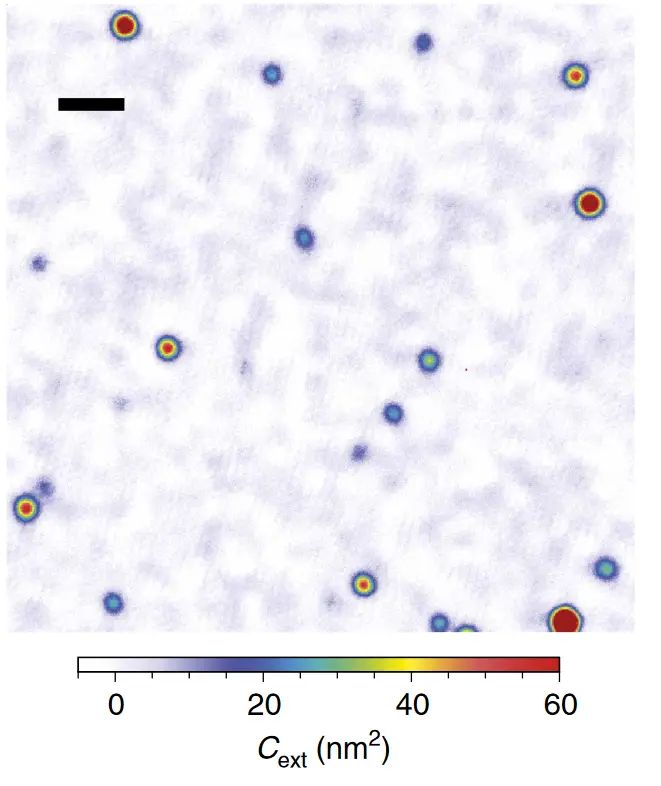

We offer a novel, ultra-sensitive raster-scanning absorption microscope for the detection and quantitative characterization of nanoscale particles, low-dimensional materials, thin films, and defects in vacuum, air, and liquid environments.

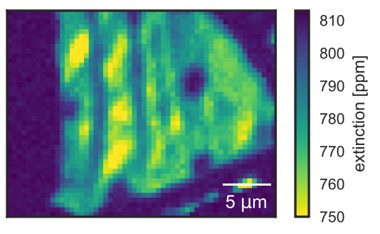

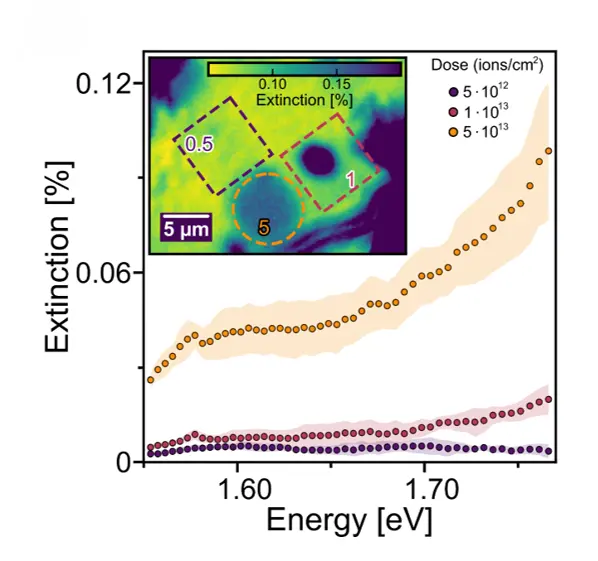

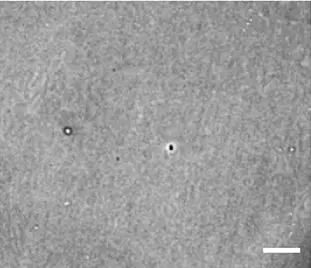

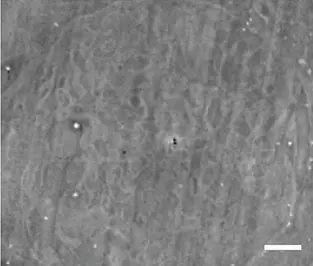

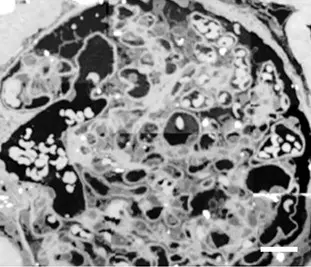

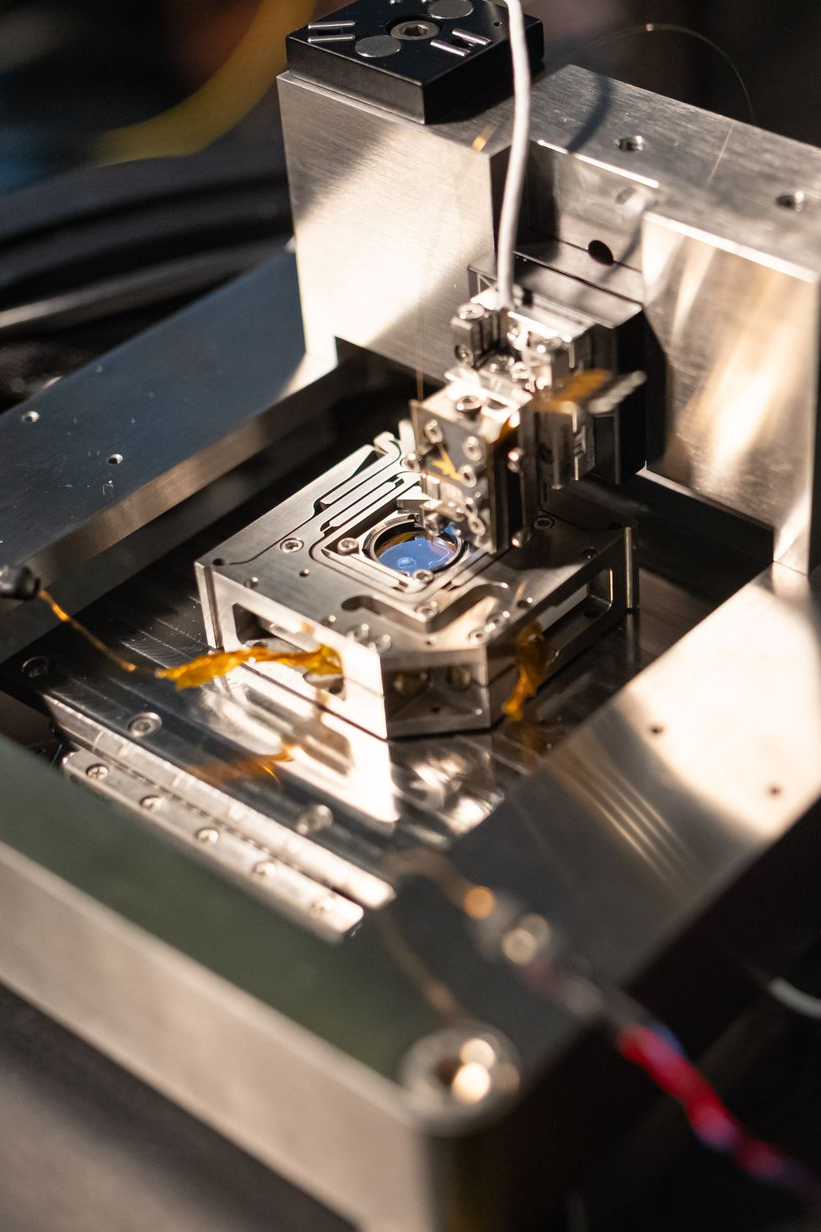

In this system, conventional lenses and objectives are replaced by a pair of high-reflectivity mirrors, significantly enhancing light–matter interaction. One mirror is macroscopic and serves as the sample substrate, while the second is microscopically small. By raster-scanning the sample with high speed and precision, the system generates absorption images with unprecedented sensitivity—down to 0.1 parts per million—exceeding the performance of conventional techniques by a factor of 1,000. This capability reveals optically "invisible" samples, such as individual nanoparticles, single defects, and even single molecules.

The microscope is capable of imaging areas up to 300 × 300 µm² within a few seconds, achieving diffraction-limited spatial resolution. At a fixed point, time-resolved measurements can be performed with a temporal resolution on the order of a few microseconds.

Each mirror set provides a spectral bandwidth of 100–150 nm. A wide selection of stock and custom mirrors is available, all of which can be exchanged in under 30 minutes, allowing full coverage of the visible to near-infrared (VIS/NIR) spectral range.

Control is managed through a Python-based software suite that includes standard measurement and analysis routines. The software also supports integration with additional laboratory instrumentation.

The microscope is also highly sensitive to scattering and also support fluorescent imaging, dielectric index and phase measurements as well as polarization control.

For advanced spectroscopic applications, an optional module enables high-resolution spectroscopy with spectral resolution down to 0.02 nm in under one second, as well as the acquisition of hyperspectral maps.

Performance specs

ΔA<0.0001%

Ultra sensitive

Δt<1ms

Time resolution

0.1mm²

Image size

1 FPS

Fast imaging

Δλ 150nm

Hyperspectral maps

350-2000nm

Broad spectral range

Features

FULL INSIGHT

Characterize individual nanoparticles, single defects and thin films on an unprecedented level with ultra-sensitive microscopy and hyperspectral imaging.

FULL CONTROL

Measurement and analysis modules in Python for easy and fast data acquisition and integration with your lab routines.

FULL SUPPORT

Close support by experts from the design of the experiment till the publication.

Applications

Our microscope can image and measure a wide range of materials, prepared using techniques such as spin-coating, drop-casting, stamping, and more.

Nano-particles

Measure presence, spectra, distribution and location of nanoparticles, e.g. nm-sized gold or Perovskites.

Your material

Use our technology as a Pilot User

Be the first to try our new technology by becoming a pilot user. We will work together with you to make visible what has been hidden so far. Just contact us!

Scanning cavity technology

How our scanning cavity microscope works:

Funded by the European Union

We are proud that this Project is funded by the competitive European Innovation Council under a EIC Transition Project (Grant agreement number 101146834). This is a program to fund highly innovative Ideas of SMEs to Validate technologies and develop business plans. It supports the maturation and validation of novel technologies from the lab to the relevant application environments.